OEM Magnetic Button Factory – Bulk & Wholesale Solutions for Handbags & Gift Boxes

Premium OEM Magnetic Button Factory – Bulk & Wholesale Solutions for Handbags & Gift Boxes

Unmatched Precision in Magnetic Fastener Manufacturing

Welcome to Peicheng, a leading OEM/ODM manufacturer specializing in high-performance magnetic buttons, invisible magnets, and magnetic closures for luxury handbags, gift boxes, and premium packaging. With advanced production technology and strict quality control, we deliver durable, strong, and precisely engineered magnetic fasteners in bulk quantities for global brands.

Our vertically integrated manufacturing process ensures consistent magnetic strength, corrosion resistance, and flawless finishes, making us the trusted supplier for fashion accessories, leather goods, and high-end packaging industries.

Advanced Magnetic Production Process – Engineered for Excellence

Our state-of-the-art magnetic button production follows a scientifically optimized workflow to guarantee superior magnetic performance, longevity, and aesthetic perfection. Below is our detailed manufacturing process:

🔹 Front-End Production – Creating the Magnetic Core

1. Material Preparation

High-purity rare-earth elements (Neodymium, Samarium-Cobalt) or ferrite materials are selected based on application requirements.

Raw materials undergo spectral analysis to ensure chemical composition accuracy.

2. Melting & Alloying

Metals are melted in a vacuum induction furnace to prevent oxidation.

Precise alloying under controlled atmosphere ensures uniform magnetic properties.

3. Hydrogen Decrepitation (HD Process)

The alloy is exposed to hydrogen gas, causing it to fracture into fine powder.

This step enhances magnetic alignment efficiency in later stages.

4. Jet Milling (Pulverization)

The hydrogen-decrepitated alloy is jet-milled into micron-sized particles.

Particle size distribution is laser-analyzed for consistency.

5. Pressing (Orientation & Compaction)

Powder is loaded into molds and compressed under a magnetic field (up to 2+ Tesla) to align magnetic domains.

Isostatic pressing ensures uniform density & structural integrity.

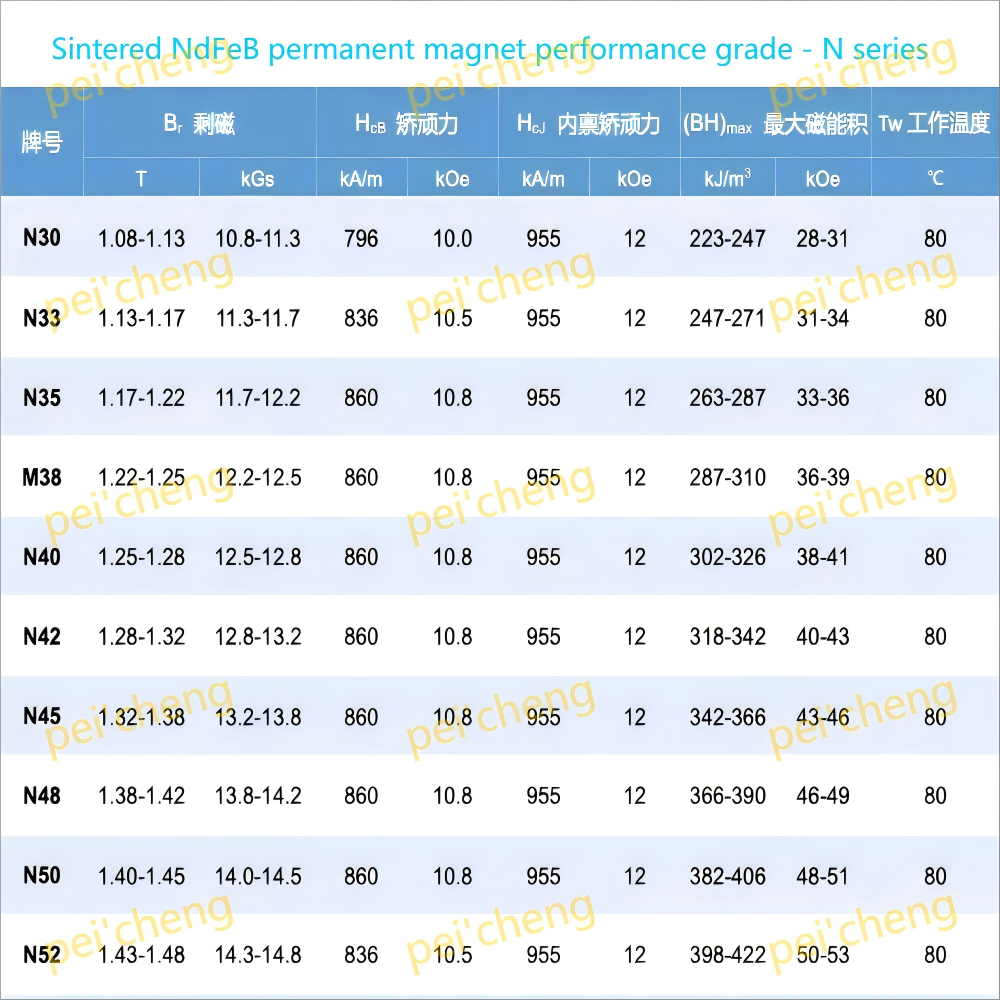

6. Heat Treatment (Sintering)

Pressed blanks are sintered in a vacuum furnace at 1,000–1,200°C to fuse particles into a solid structure.

Tempering & aging optimize coercivity & thermal stability.

✅ Output: Magnetic Blanks (Unmagnetized, Unfinished Magnets)

🔹 Back-End Processing – Precision Finishing

7. Machining (CNC Grinding & Cutting)

Sintered magnets are precision-ground to exact dimensions (±0.02mm tolerance).

CNC machining creates custom shapes (discs, countersunk, custom designs).

8. Grain Boundary Diffusion (For High-Temp Magnets)

Heavy rare-earth coating (Dy, Tb) is applied via diffusion process to enhance heat resistance (up to 200°C).

9. Surface Treatment*

Multi-layer protection against corrosion & wear:

Nickel-Copper-Nickel (Ni-Cu-Ni) plating (standard)

Epoxy coating, Zinc plating, PVD coating (custom options)

Gold, Black, or Colored finishes for aesthetic appeal

10. Magnetizing

Magnets are charged in a high-intensity pulse magnetizer (up to 50,000 Oe).

Gauss meter testing verifies magnetic strength & polarity accuracy.

11. Packaging & Quality Assurance

100% inspection for dimensional accuracy, coating integrity, and magnetic performance.

Anti-demagnetization packaging (foam-lined, anti-static bags).

Custom labeling & bulk packaging options (MOQ from 1,000 pcs).

Why Choose Our Magnetic Buttons?

✔ Superior Holding Force – Customizable strength (1N to 20N+) for secure closures.

✔ Corrosion-Resistant – Salt spray tested (48+ hours) for long-term durability.

✔ Aesthetic Versatility – Invisible embedded magnets or decorative metal finishes.

✔ Bulk & Wholesale Supply – Competitive pricing for large orders (OEM/ODM supported).

✔ Fast Turnaround – 15-30 days lead time for bulk production.

Applications:

Luxury Handbags, Wallets, Clutches

Gift Boxes, Jewelry Packaging, Watch Cases

Diaries, Leather Goods, Apparel Fasteners

Industrial & DIY Magnetic Solutions