产品详情

---

Shank Buttons: The Seamless Solution for Elegant Fastening

When it comes to high-end garments and refined accessories, every detail matters. From the texture of the fabric to the tiniest hardware element, quality speaks through craftsmanship. Among the many types of buttons available in fashion and accessory manufacturing, Shank Buttons—also known as Stem Buttons or Loop Buttons—stand out for their smooth appearance, durability, and versatile applications.

Whether you're producing tailored jackets, classic coats, fine leather handbags, or designer shoes, the choice of button can dramatically influence the finished look and performance. Here’s why Shank Buttons have long been the industry’s quiet heroes.

What Is a Shank Button?

A Shank Button is a type of button that features a raised loop (or shank) on the back rather than holes through the face. This loop is used for stitching the button to the fabric or material, allowing the button to sit slightly away from the surface. The result? A neat, smooth finish on the front, with no visible sewing holes—making it perfect for more formal or decorative purposes.

Alternative Names: Stem Button and Loop Button

The term “Shank Button” is the most widely recognized in the garment industry. However, depending on regional use, material type, or manufacturer preference, these buttons may also be referred to as:

Stem Buttons – emphasizing the vertical or cylindrical "stem" structure on the back

Loop Buttons – highlighting the rounded loop used for sewing

Back Loop Buttons – focusing on the loop located behind the button face

No-Hole Buttons – used to contrast them with sew-through buttons

Though the naming varies, they all serve the same primary function: offering a clean, elevated profile while ensuring strong and flexible attachment.

Why Choose Shank Buttons?

Shank Buttons are especially favored in applications where aesthetic appeal and fabric movement are essential. Here are some of the key advantages:

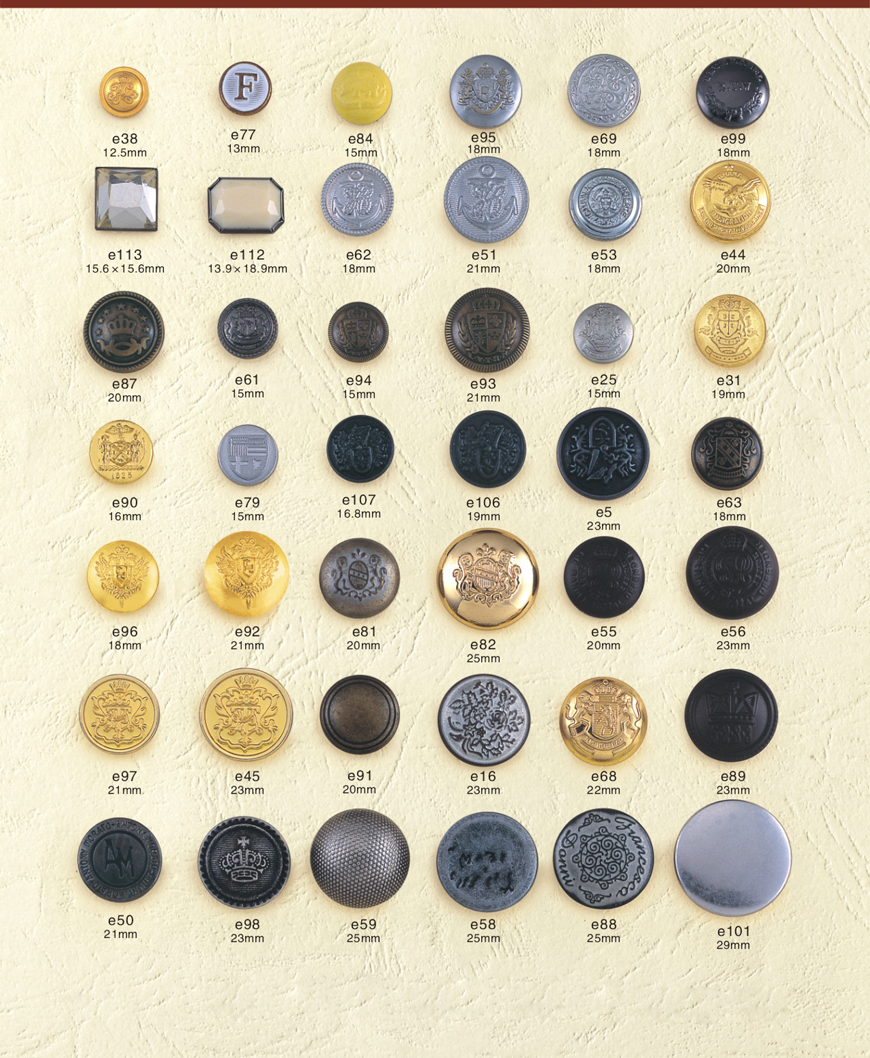

✔ Elegant Appearance

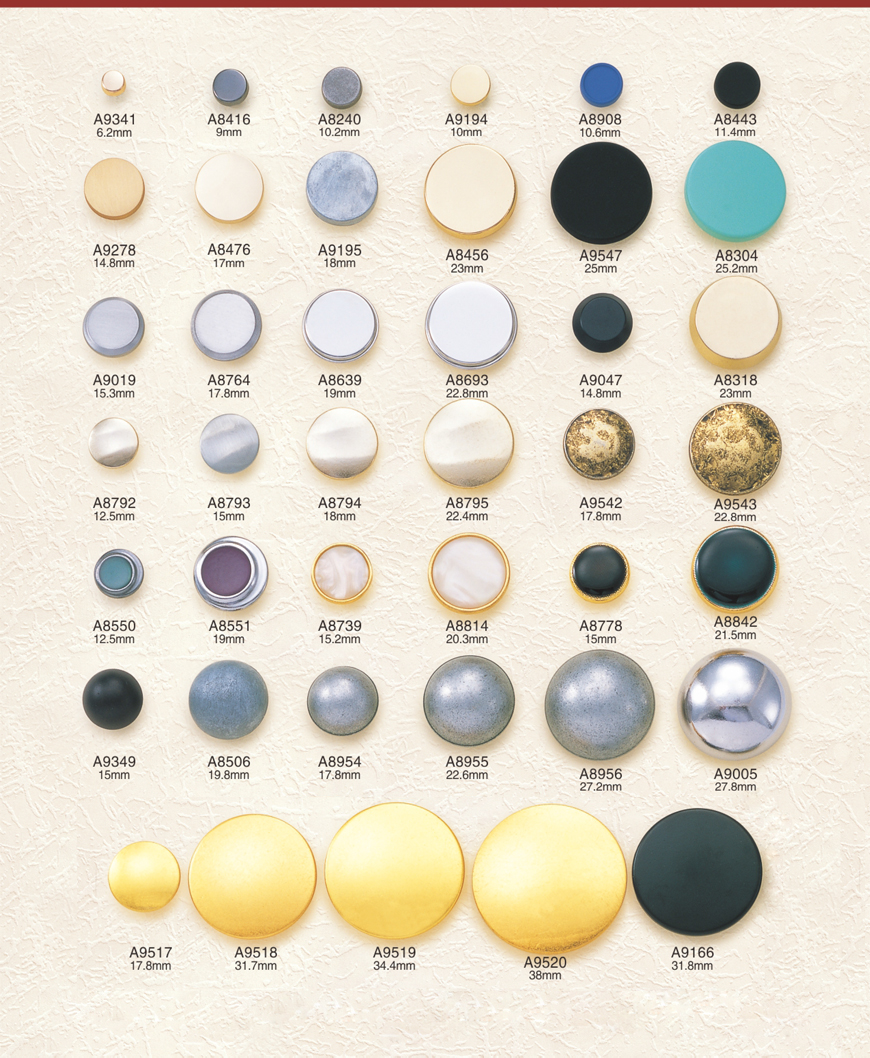

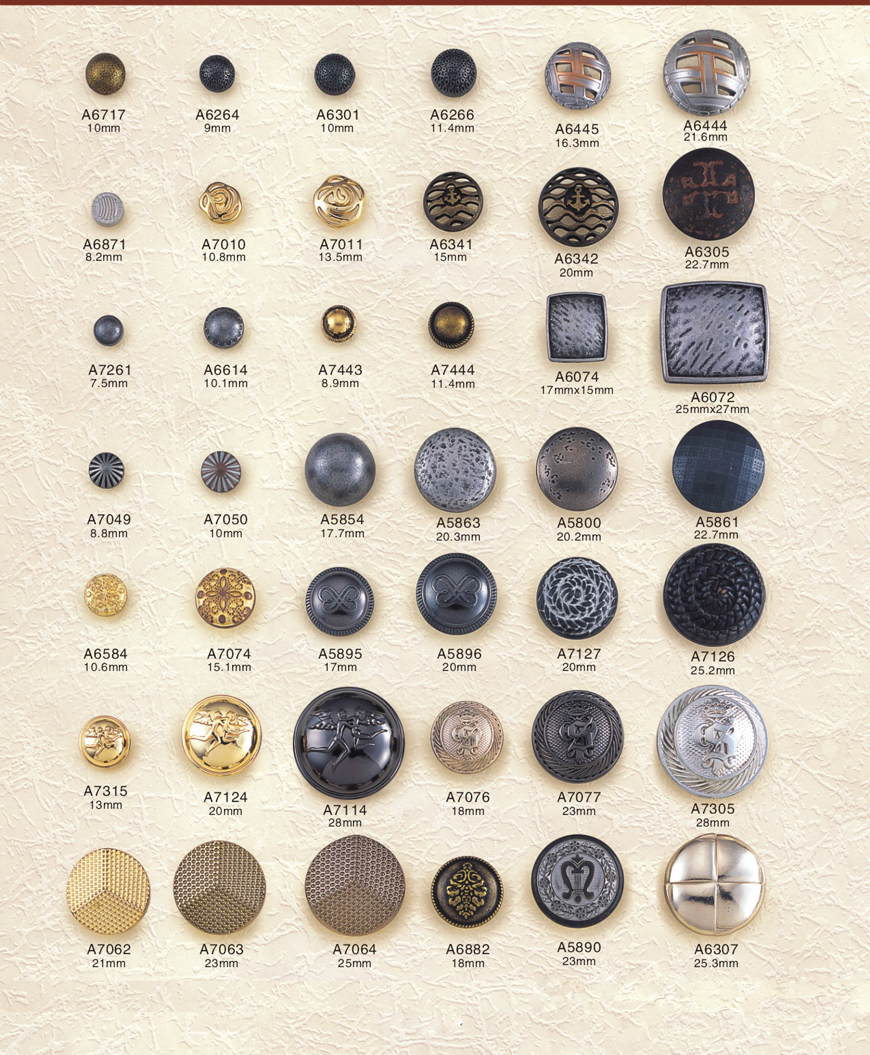

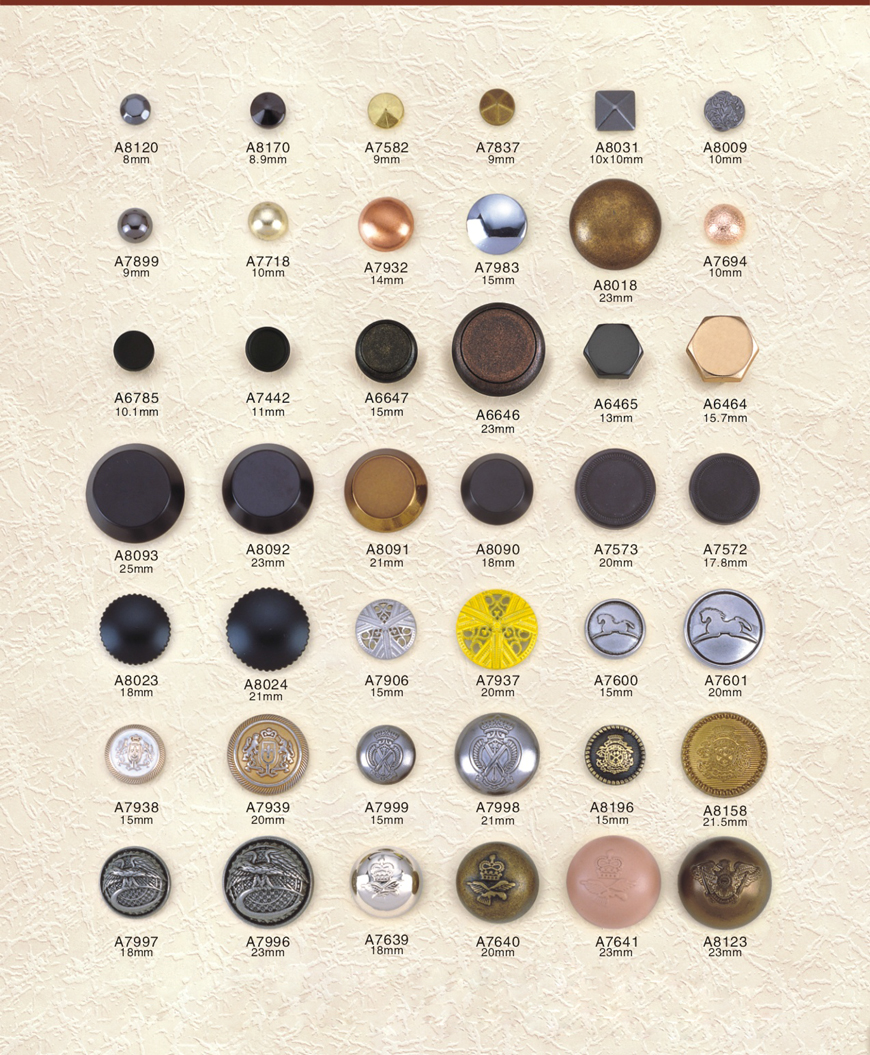

Because they lack front-facing holes, Shank Buttons offer a more polished, uninterrupted surface. This makes them ideal for fashion-forward designs or luxury applications.

✔ Easy Fabric Movement

The shank or loop provides spacing between the button and the fabric, making it easier to fasten thicker materials or layered fabrics without puckering.

✔ Durability

The back loop allows for reinforced stitching, which reduces wear and tear on both the button and the garment.

✔ Versatility

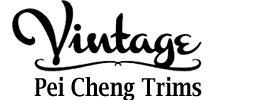

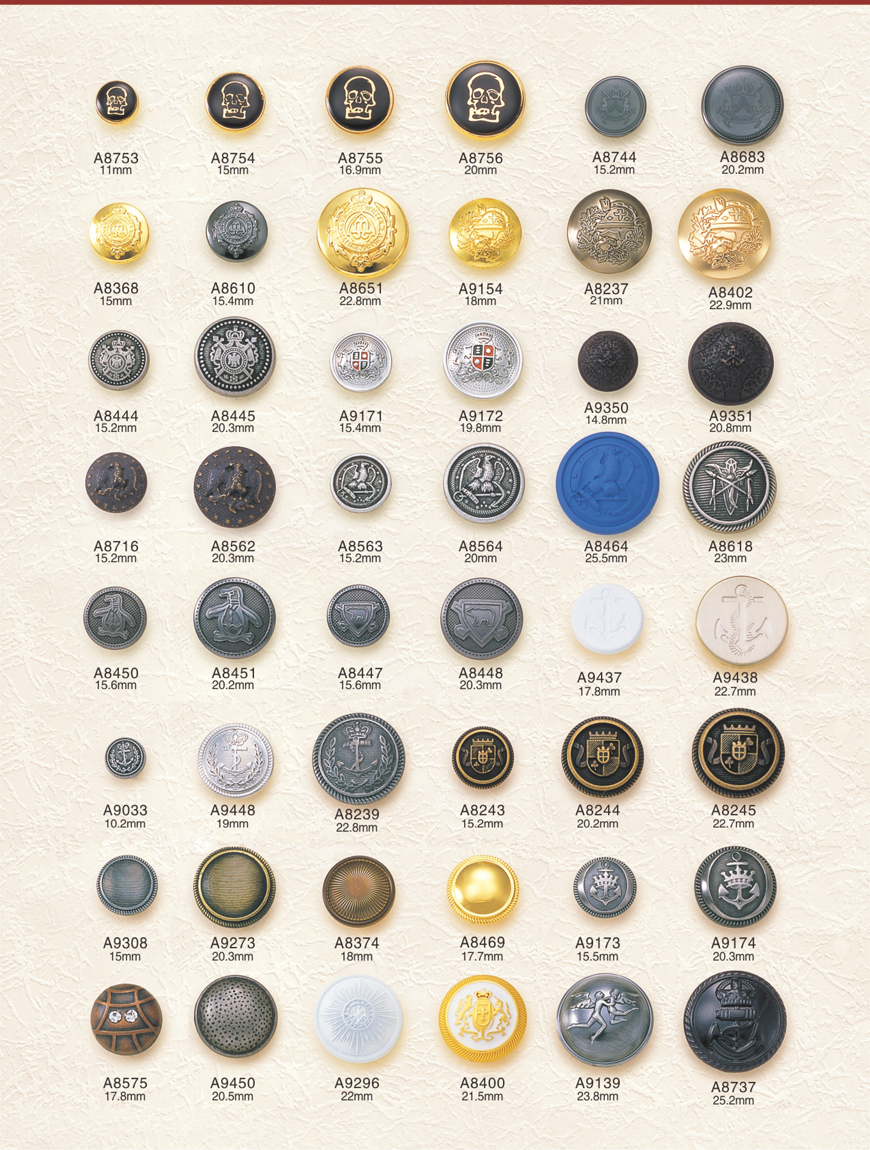

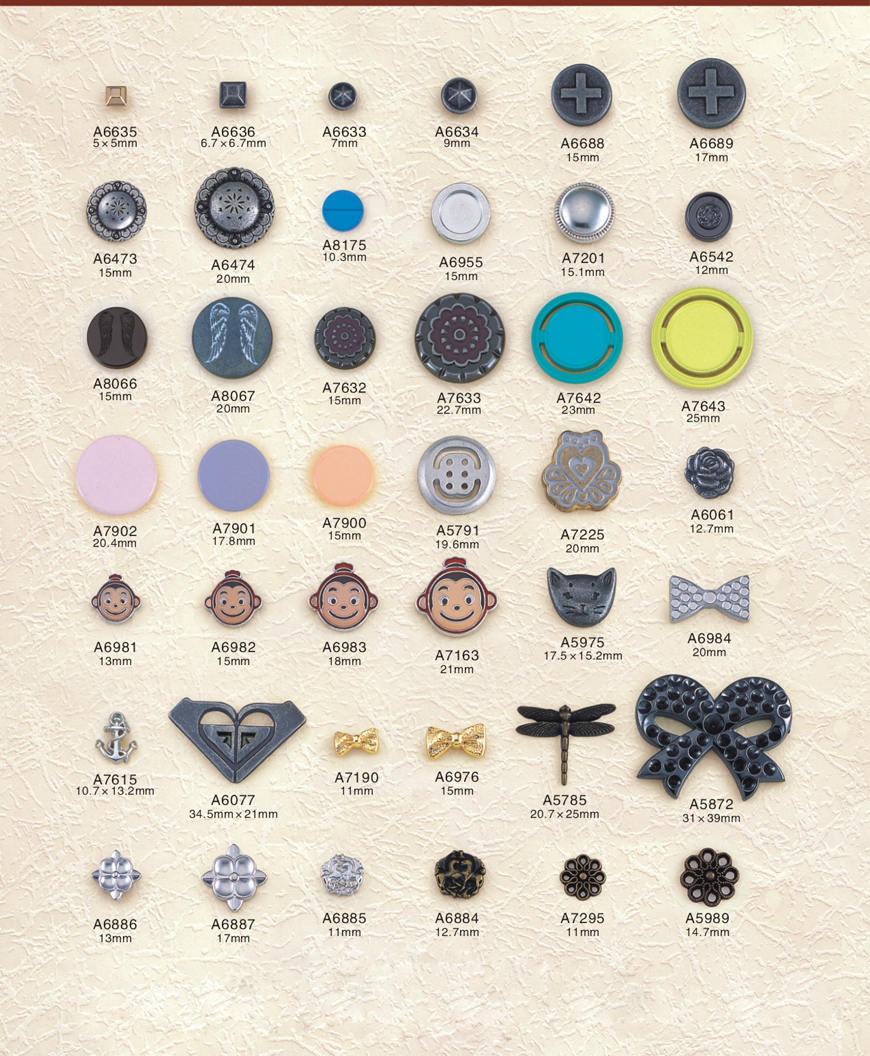

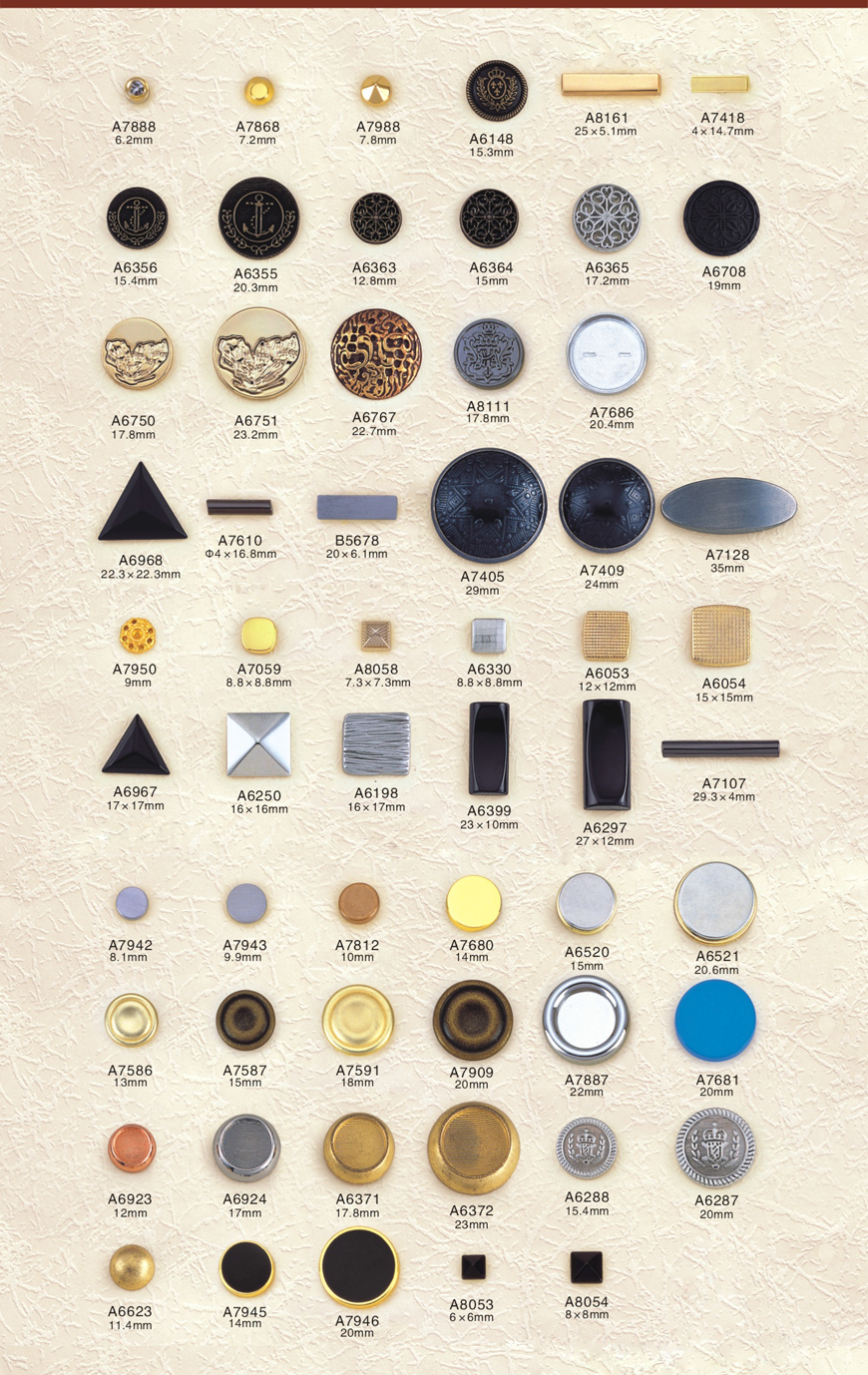

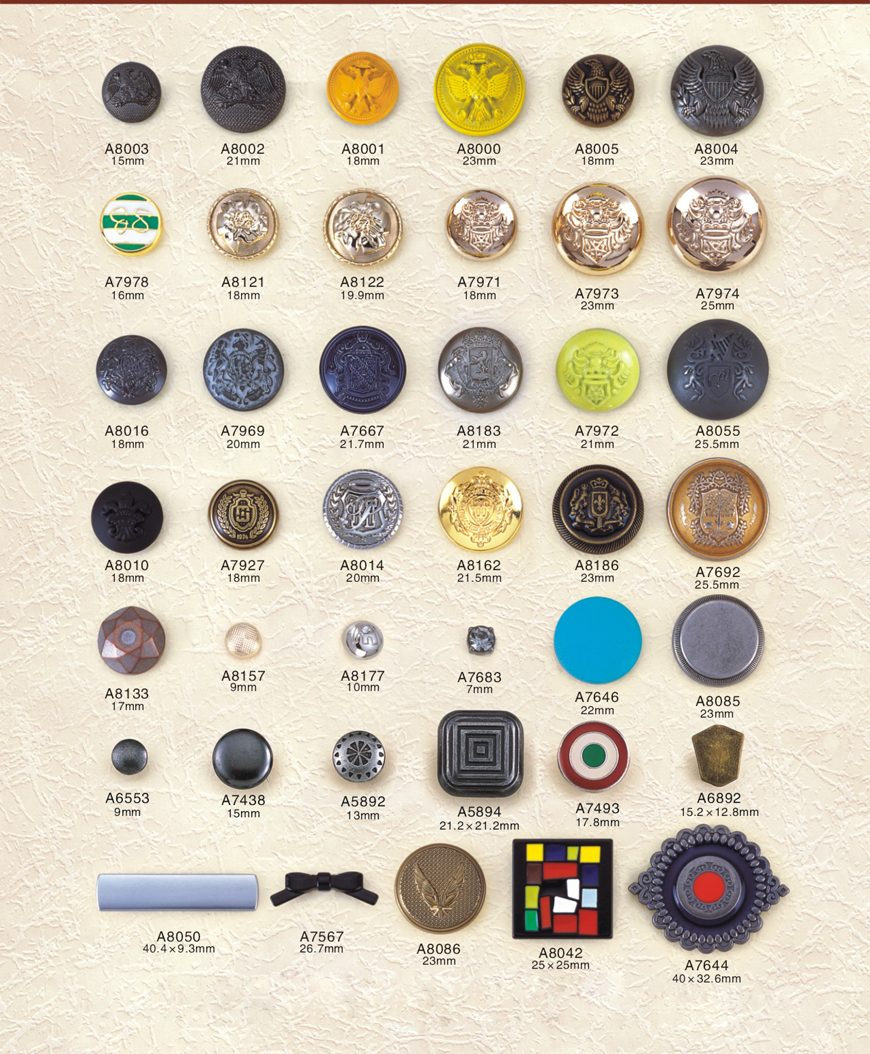

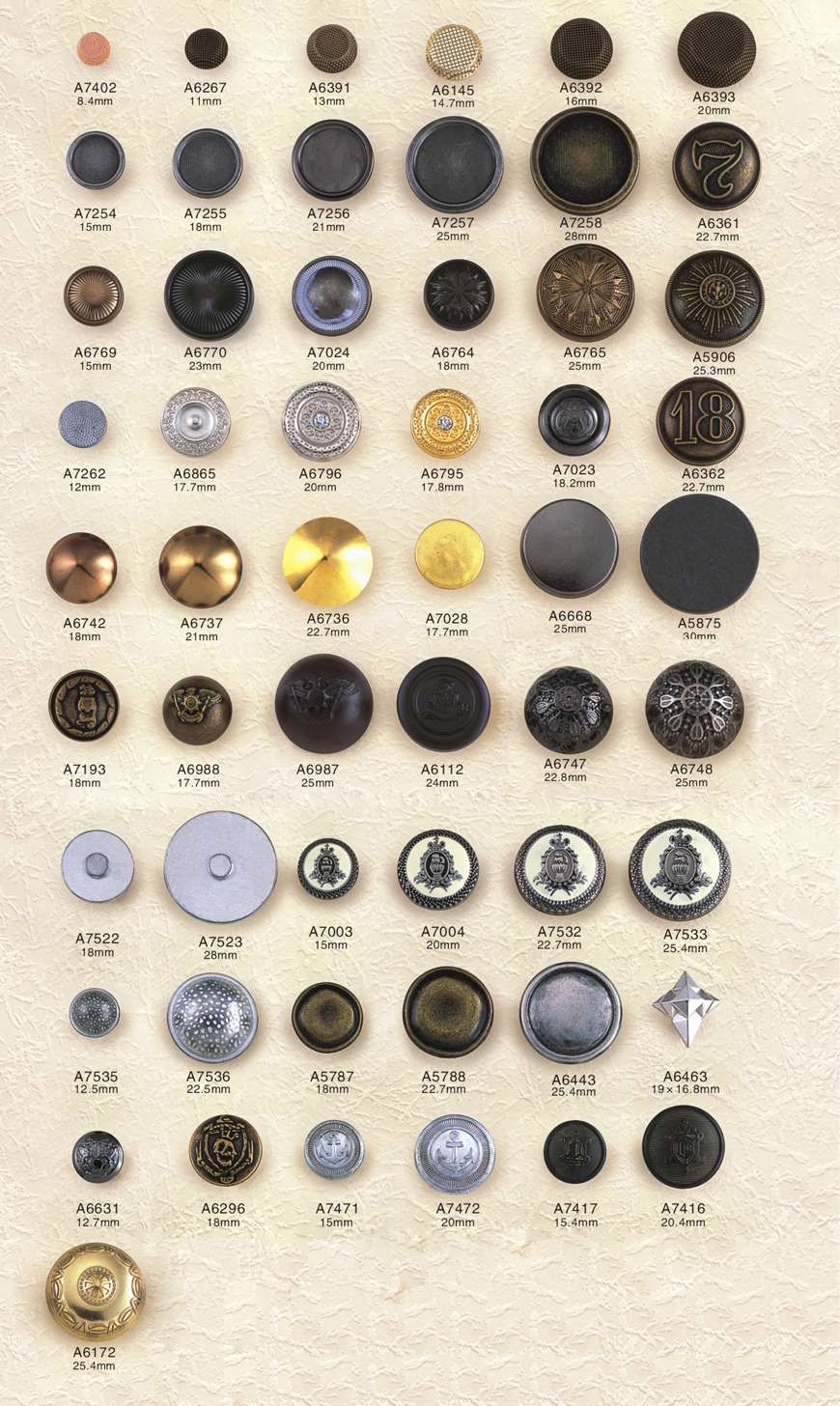

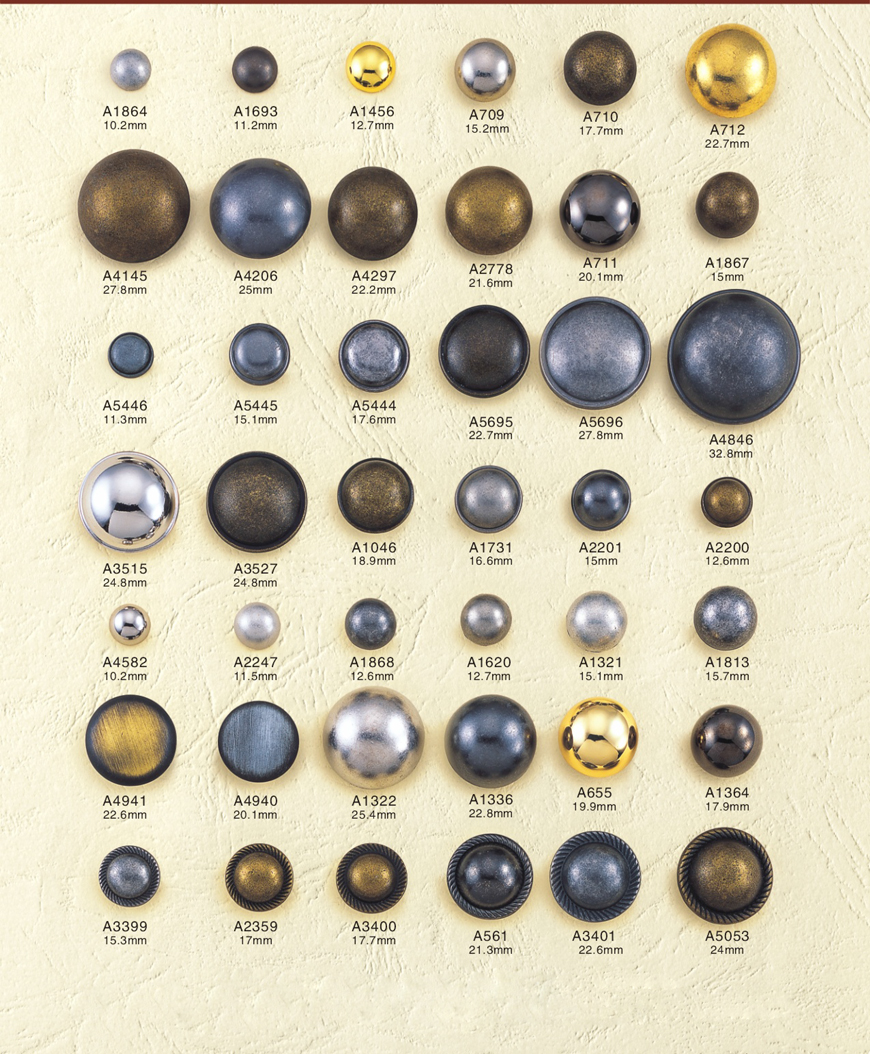

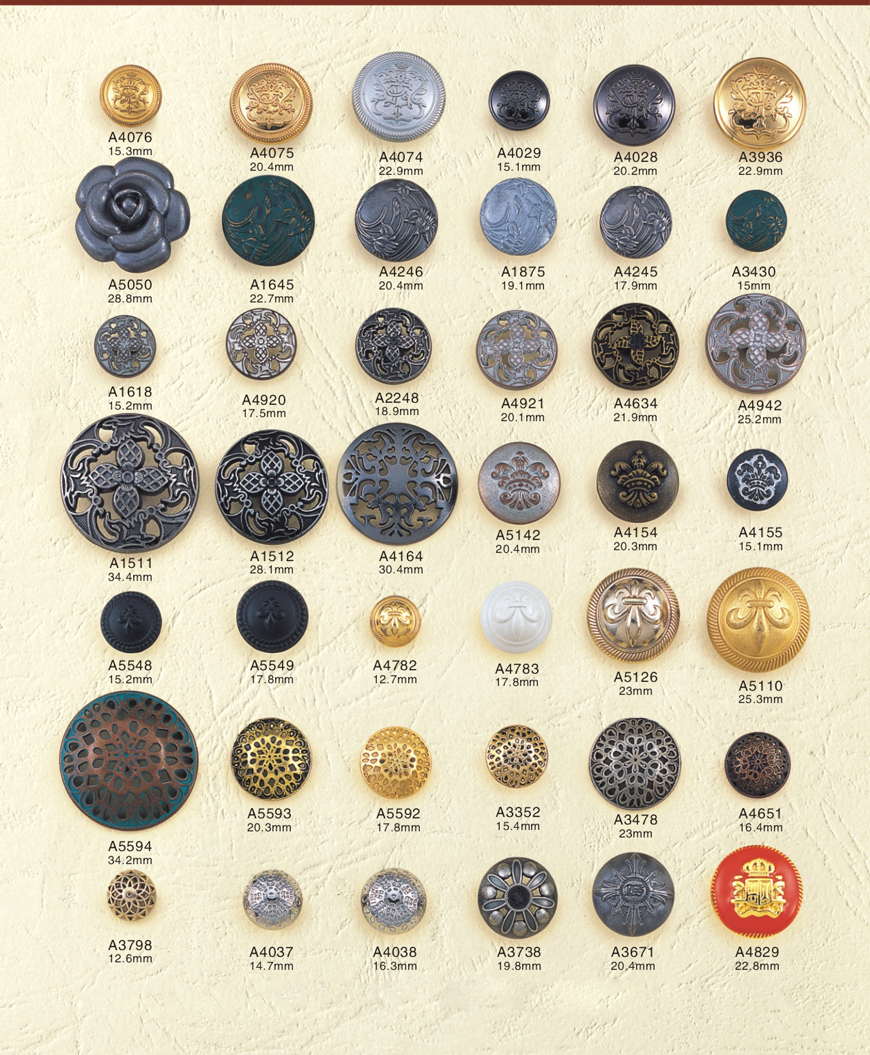

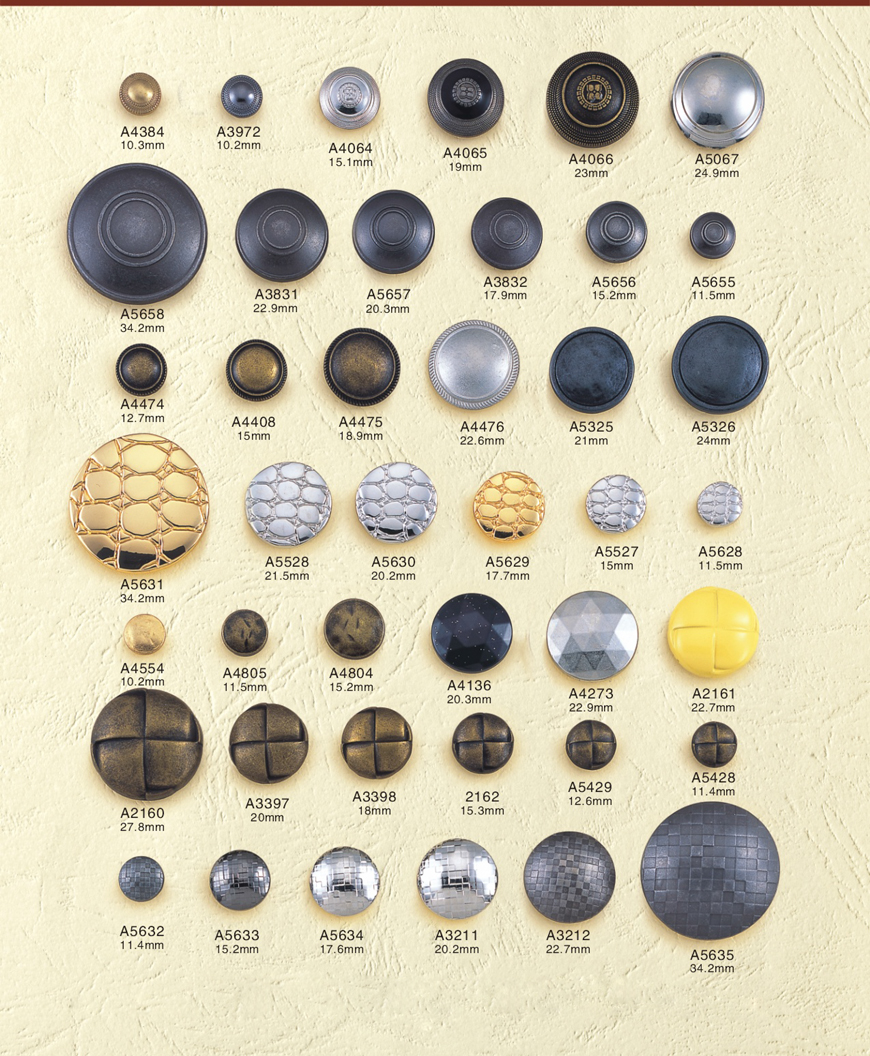

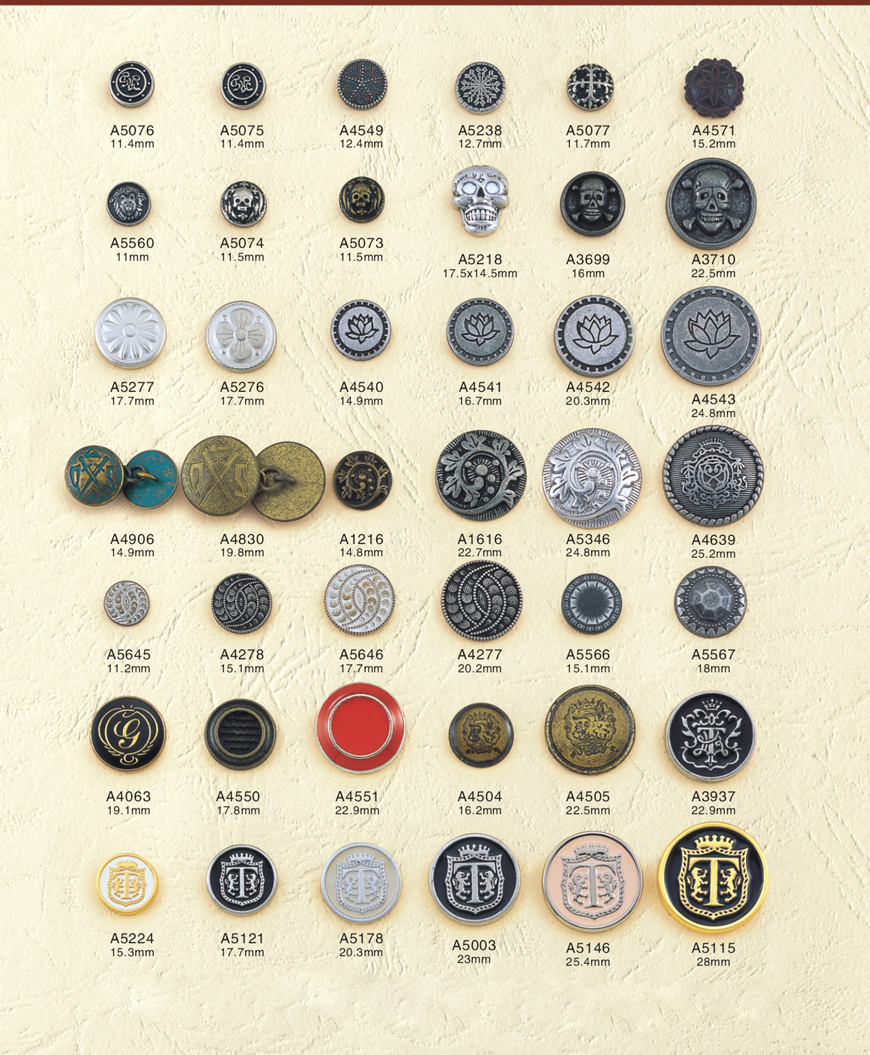

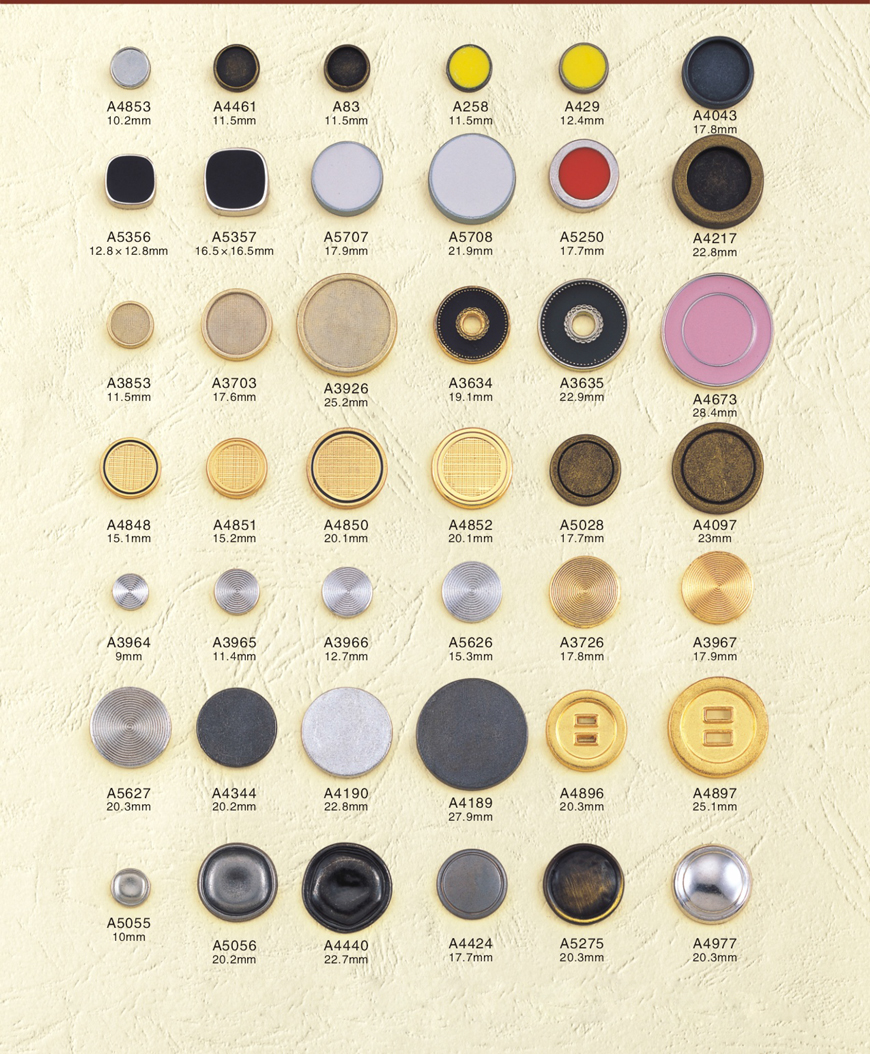

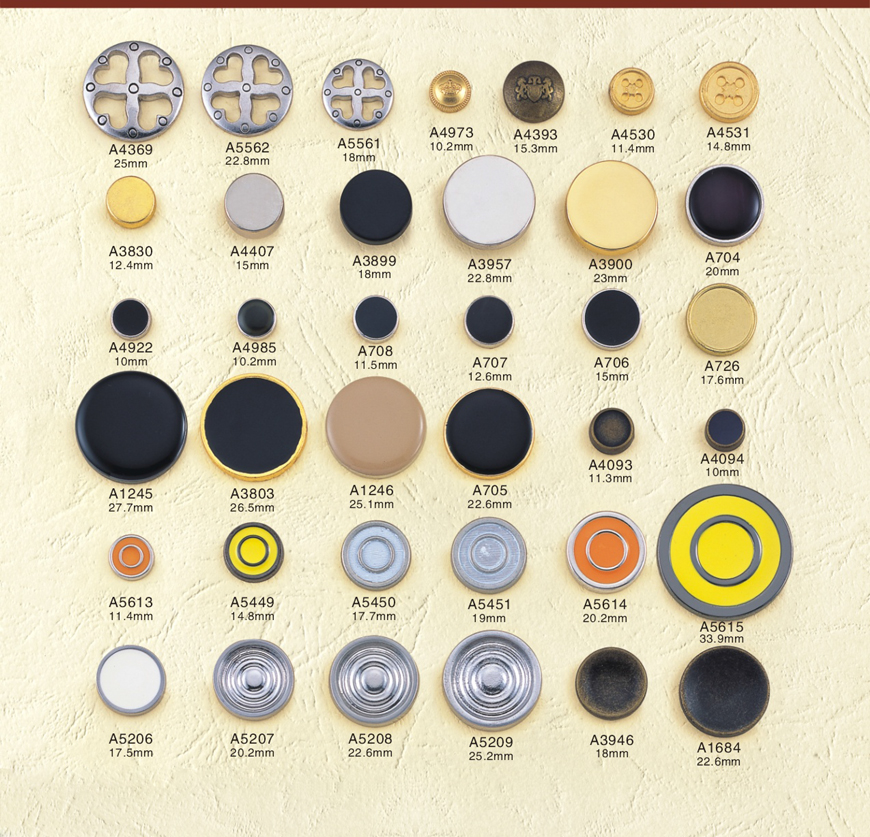

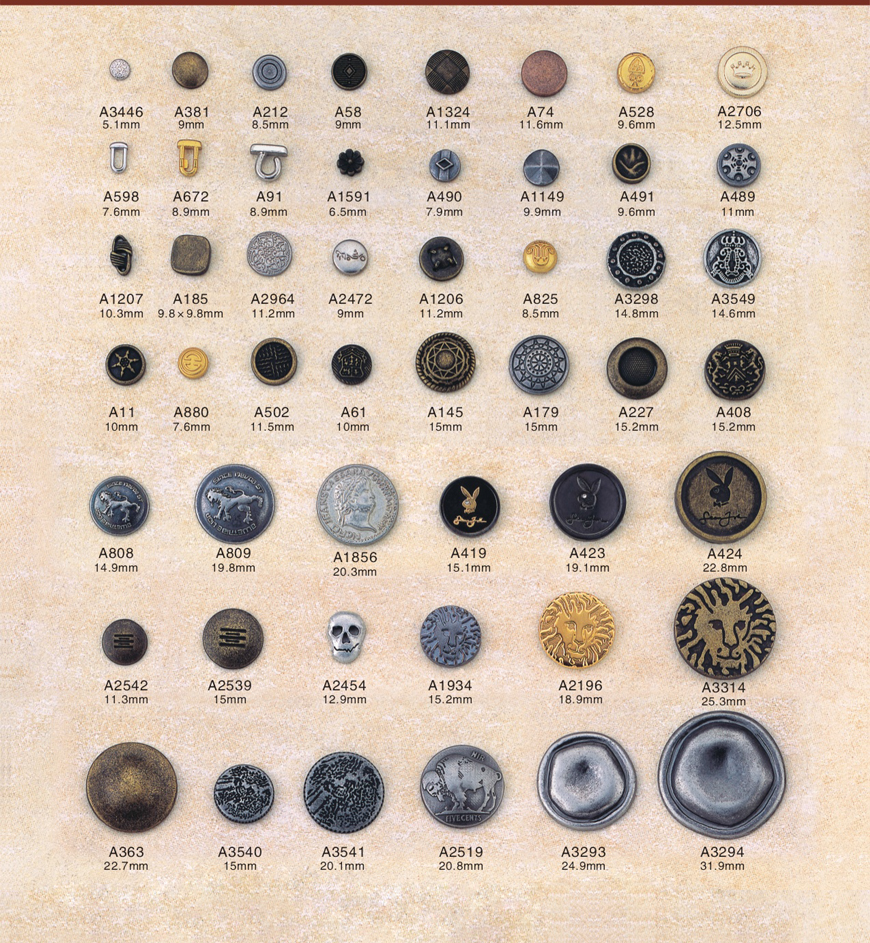

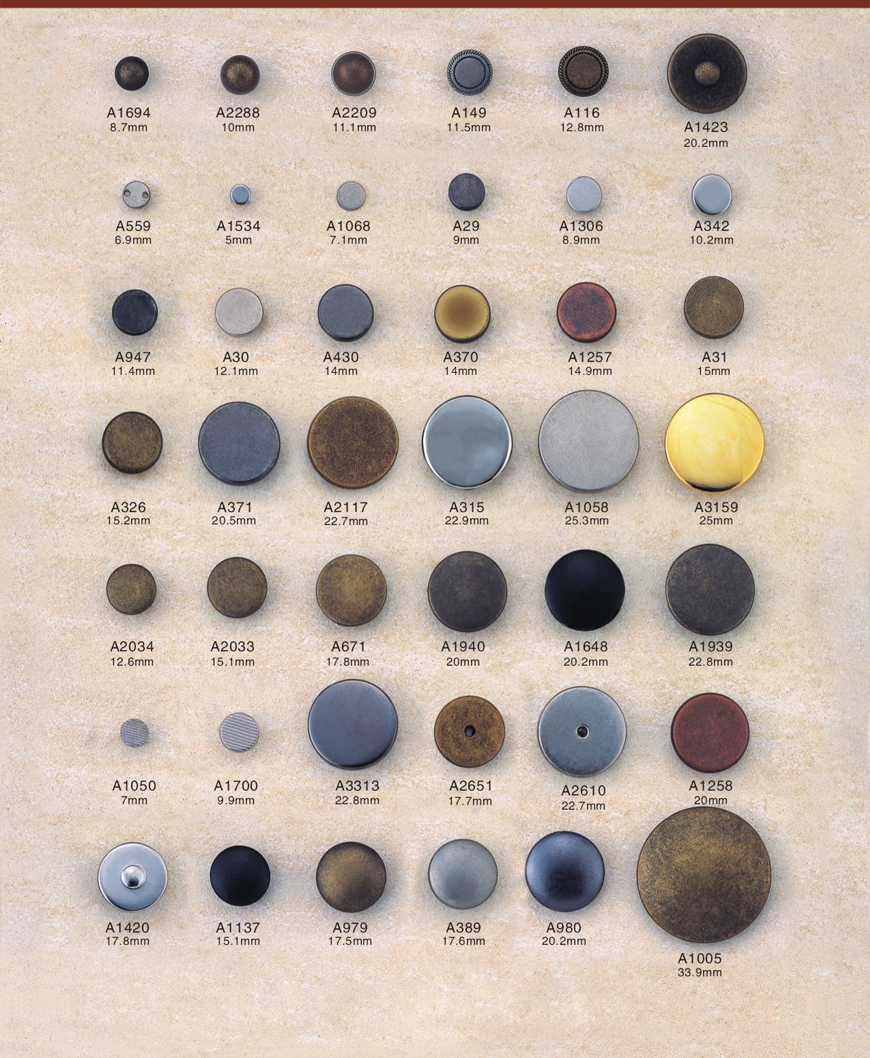

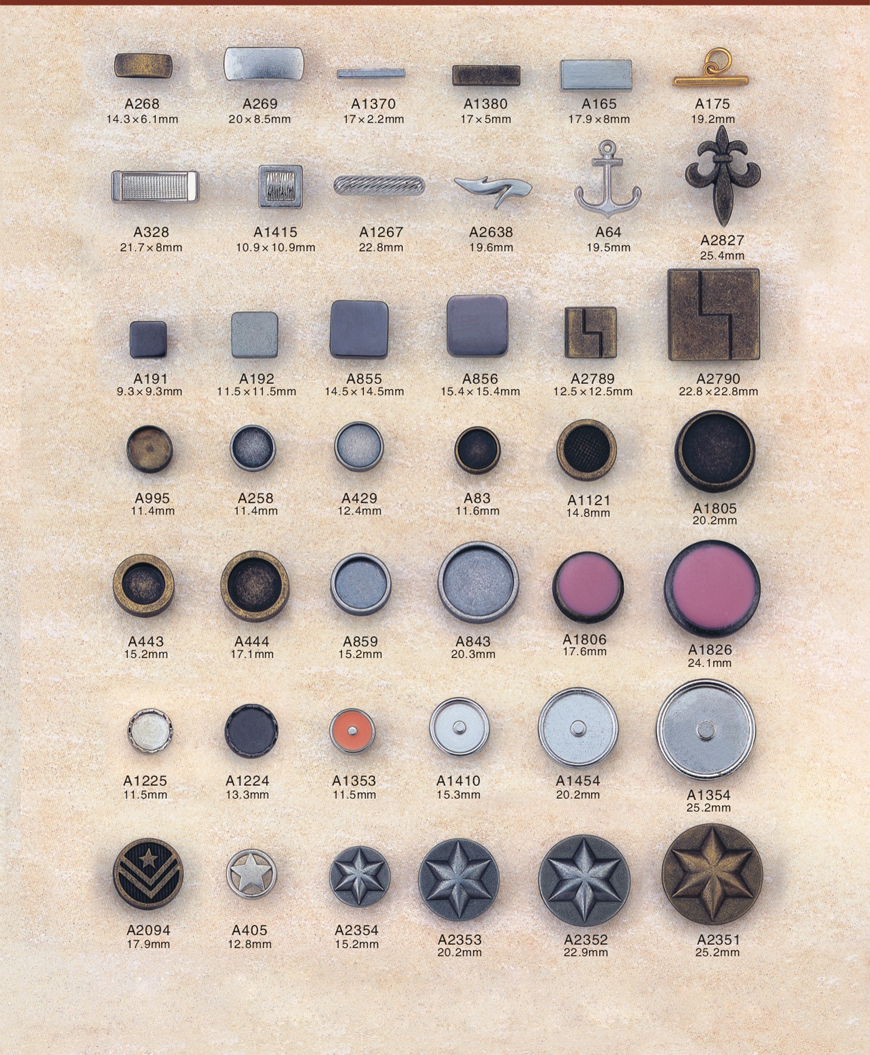

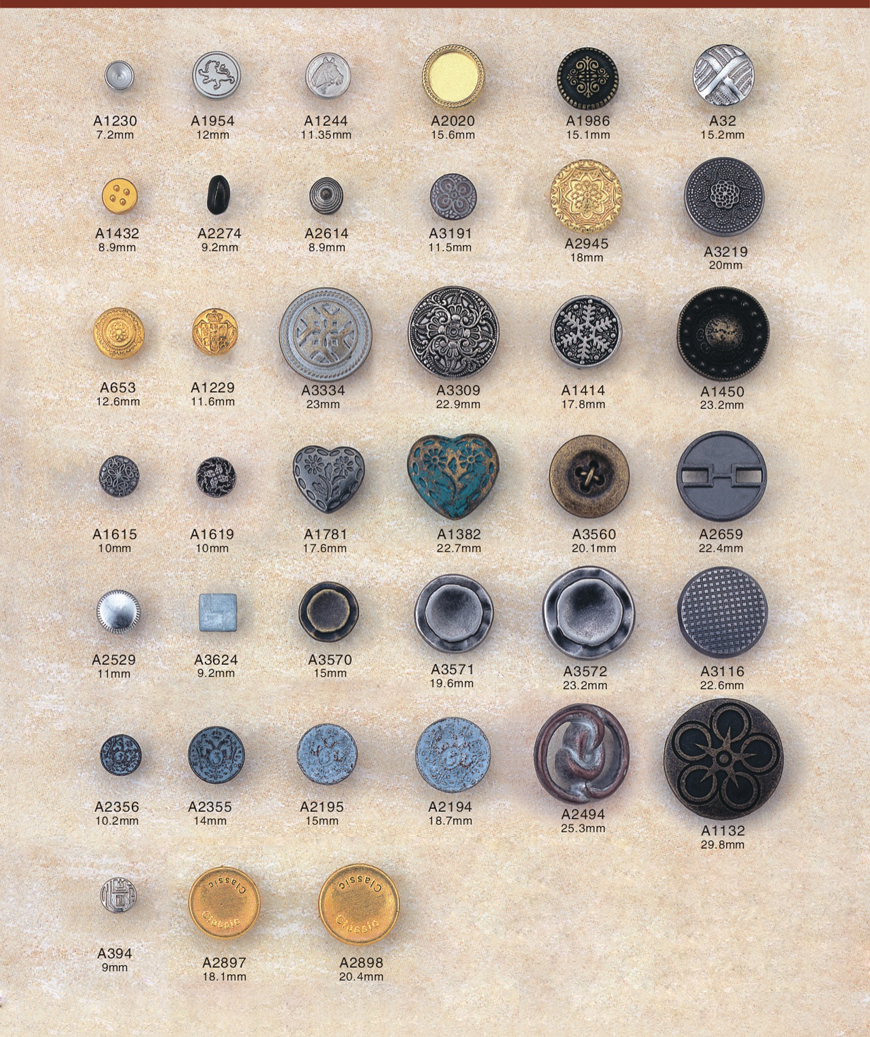

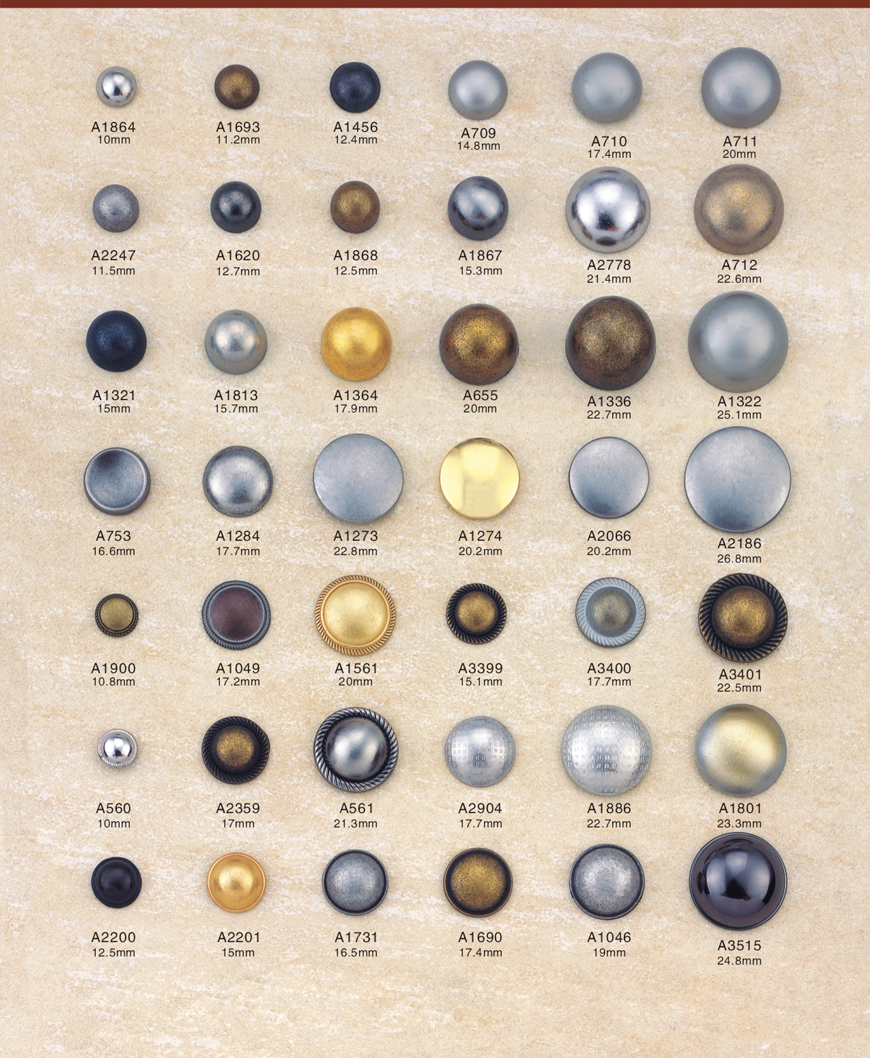

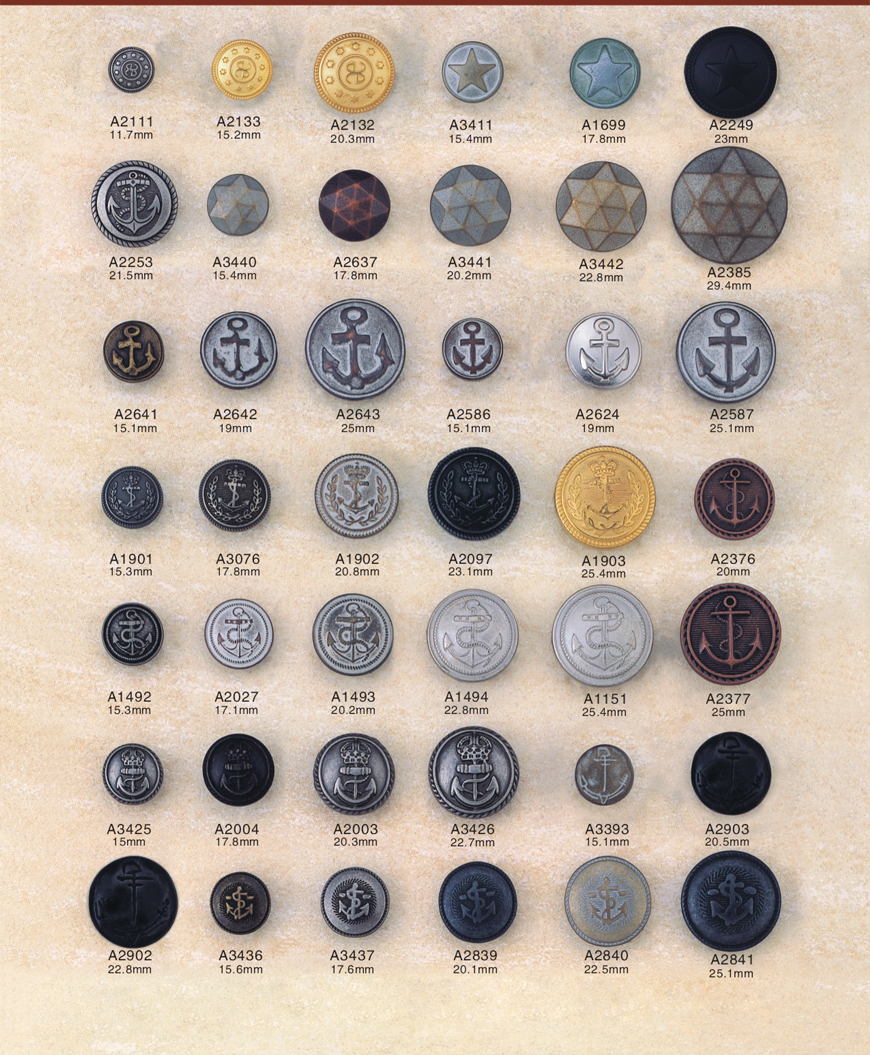

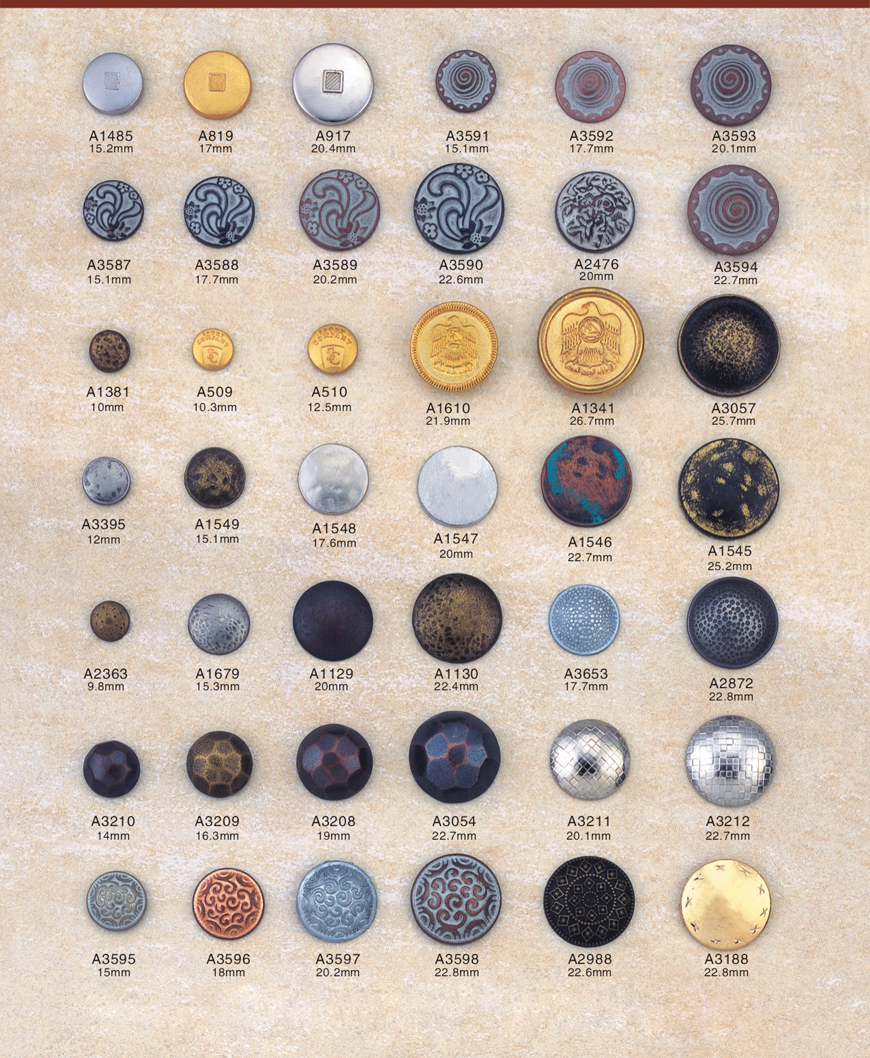

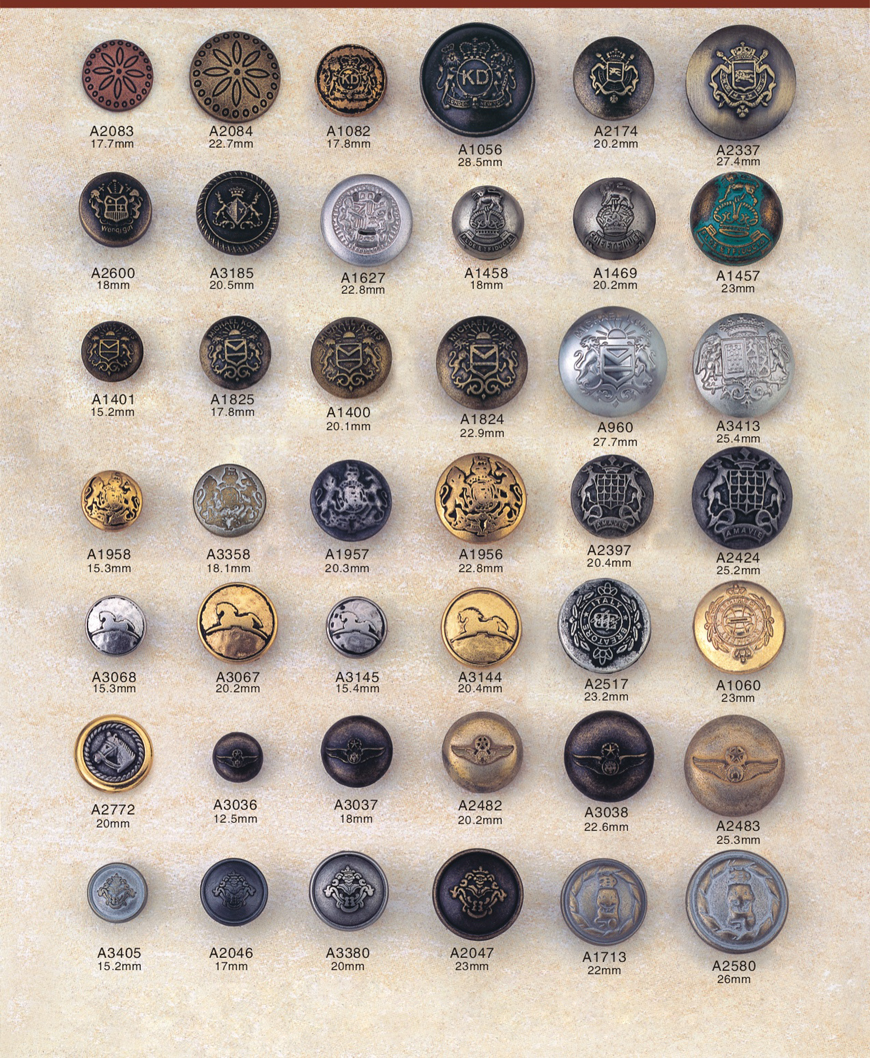

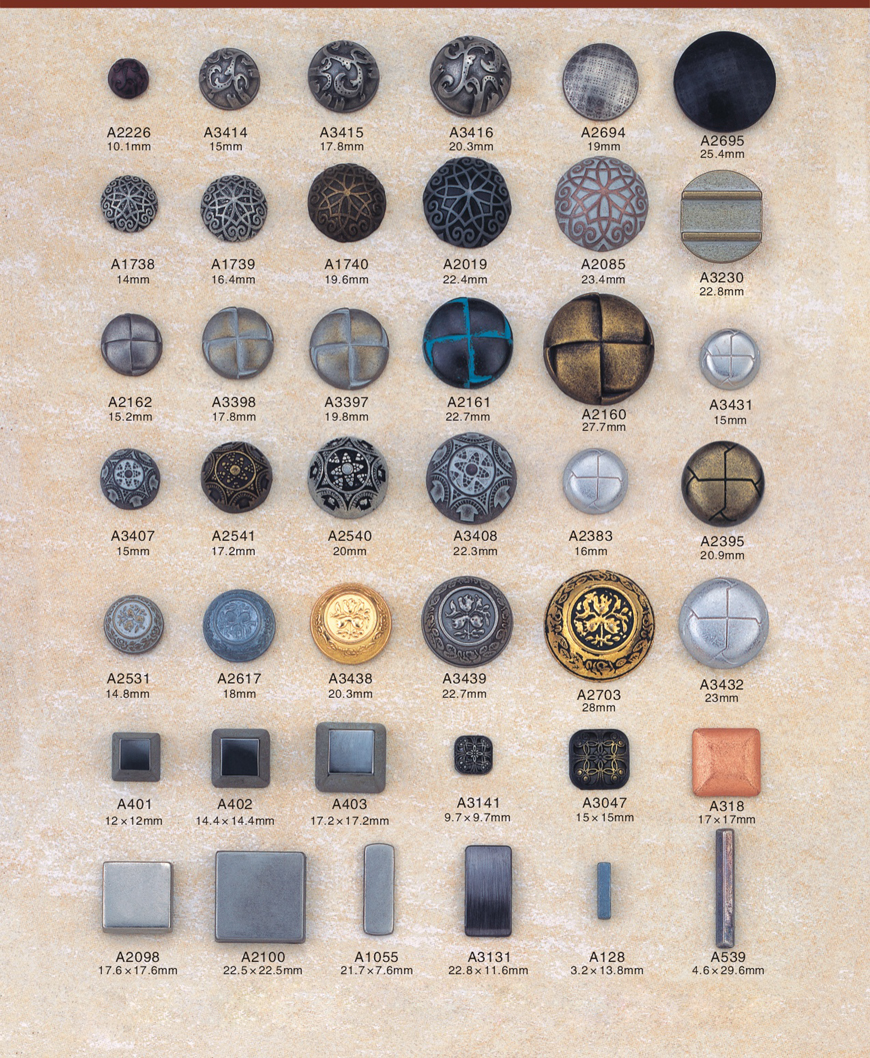

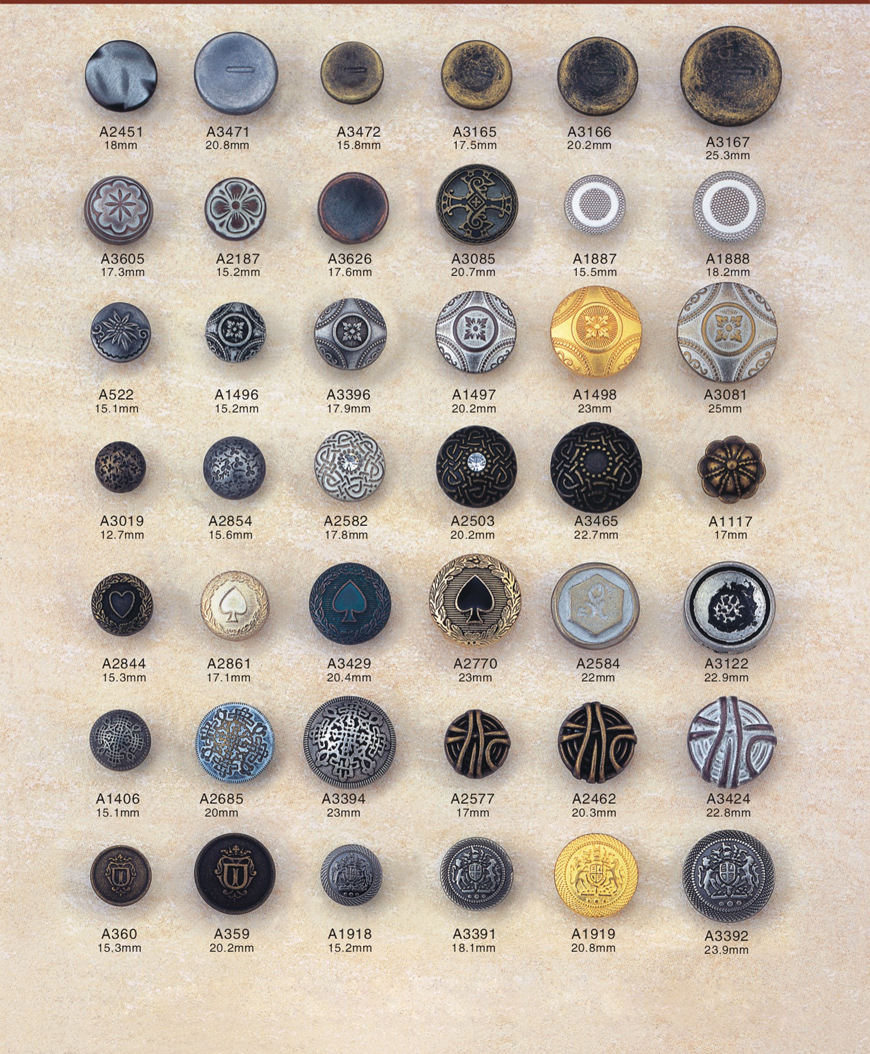

Available in materials such as zinc alloy, brass, stainless steel, resin, or plastic, Shank Buttons come in various finishes and sizes to suit both fashion and utility applications.

Applications of Shank Buttons

Shank Buttons are widely used across multiple industries, including:

Apparel – Suits, trench coats, dresses, uniforms, knitwear

Accessories – Handbags, hats, gloves, belts

Footwear – Loafers, boots, decorative shoe straps

Home Decor – Cushions, upholstery, drapery

Comparison: Shank vs Sew-Through Buttons

| Feature | Shank Button | Sew-Through Button |

|---|---|---|

| Stitching Method | Sewn through back loop/shank | Sewn through front holes (2 or 4) |

| Front Appearance | Smooth, hole-free surface | Visible stitching |

| Ideal For | Formalwear, leather goods, décor | Casual wear, shirts, uniforms |

| Spacing from Fabric | Raised – allows fabric movement | Flat against fabric |

| Aesthetic Appeal | Premium, decorative | Simple, functional |

| Common Materials | Metal, resin, plastic, horn | Plastic, resin, wood |

Things to Consider When Choosing Shank Buttons

Before incorporating Shank Buttons into your product, consider the following:

Material Compatibility: Choose corrosion-resistant metals for use with leather or outdoor gear.

Shank Strength: For heavy-duty items like luggage or boots, opt for buttons with welded or reinforced shanks.

Plating Finish: Make sure the electroplating finish (nickel, antique brass, gunmetal, etc.) matches your design and wear resistance requirements.

Attachment Method: Some shank buttons are designed to be hand-sewn, others may be compatible with industrial machinery.

Conclusion: Small Detail, Big Difference

Though they may seem like a minor component, Shank Buttons bring both function and finesse to your product line. Their seamless surface and reliable attachment make them a smart choice for designers who value clean aesthetics and long-lasting performance.

Whether you call them Shank Buttons, Stem Buttons, or Loop Buttons, one thing is clear: these are the go-to fasteners for elevated designs that demand more than the ordinary.

Looking to source high-quality metal or resin Shank Buttons for your production? Reach out to our team for customized solutions that meet your style and performance needs.